Diamond Dresser Tools

Overview

Diamond dressers are cutting tools used for shaping sharpening and grinding wheels. They are made from industrial-grade diamonds and have a metal base. Diamond dressing tools find application in various industries, including grinding and dressing tools, grinding stones, and other fields. Specifically, it is commonly used to dress grinding wheels and sanding belts to achieve a finer and more precise grinding surface.

Our Mission

At our core, we are dedicated to offering excellent Diamond dresser tools with unparalleled durability and performance. Our determined commitment to innovation and reliability enables us to exceed our customers‘ expectations by providing solutions targeted to their unique needs.

Our Capacity

we strive to establish enduring partnerships with our customers and become their reliable ally in the diamond dressers industry. We are dedicated to enhancing our products and services continually, guaranteeing our clients receive the most exceptional solutions available.

Find The Diamond Dresser Tools With Different Form

Single-Point Diamond Dressers

Chisel Diamond

Diamond Grit Impregnated Dressers

Blade-type Diamond Dresser

We have the capability to produce and process various types and specifications of diamond dresser tools to meet the diverse requirements of our customers.

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

Connect with the Sundi Tools Sales Team

Advantages Of Diamond Dresser Tools

-

High durability

The use of industrial-grade diamonds in our tools results in a longer service life compared to other abrasive tools.

-

Versatility

Our diamond dresser tools are suitable for many different kinds of applications because they may mold and cut a wide range of materials.

-

Precision and consistency

Our tools can create precise and consistent grinding surfaces, ensuring high-quality finished products.

-

Improved efficiency to reduce downtime

Our tools can significantly improve manufacturing processes, leading to increased productivity and reduced downtime.

Change trend of surface precision and surface finish before and after using Diamond dresser tools

| Processing times | Surface accuracy (μm) | Surface finish (Ra) |

|---|---|---|

| 1 | 0.35 | 0.023 |

| 2 | 0.31 | 0.021 |

| 3 | 0.29 | 0.019 |

| 4 | 0.28 | 0.018 |

| 5 | 0.26 | 0.017 |

| 6 | 0.25 | 0.016 |

| 7 | 0.24 | 0.015 |

| 8 | 0.23 | 0.014 |

| 9 | 0.22 | 0.013 |

| 10 | 0.21 | 0.012 |

How to Select the Proper Diamond Dressers for Grinding Wheel Dressing?

1. Type of Grinding Wheel

- Considering the type of grinding wheel being used will determine the appropriate diamond dresser types.

2. Material Being Ground

- The material being ground determines the diamond dressers concentration and type.

3. Grinding Wheel Size

- Choose a diamond dresser that matches the size of the grinding wheel.

4. Level of Precision Required

- Select a diamond dresser according to the level of precision needed for the specific task.

5. Dressing Conditions

- Consider dressing conditions, such as speed and feed rate, when selecting a diamond dresser tools

Note 1 : Typical Wheel Forms and Shape

|  |  |  |

|  |  |  |

|  |  |  |

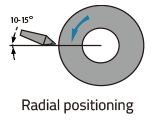

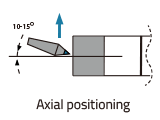

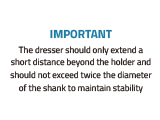

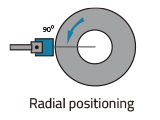

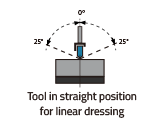

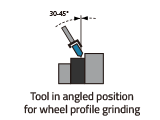

Note 2: Positioning Of The Diamond Dressing Tool

|  |  |

|  |  |

we are the best Diamond Dresser Tools manufacturers

At SUNDI, our goal is to provide you with the most cost effective and the best solutions. Our expertise, solutions, and technical support make us the ideal partner for tackling tasks, overcoming challenges, and completing projects successfully.

Customization

We customize diamond dressers based on customer needs, including diamond grit size and concentration, bond type, and dresser shape to optimize performance.

Expertise

Our experienced team provides personalized guidance to help customers choose the right diamond dresser for their needs, and technical support when required.

Quality

We create our diamond dresser tools with precision and durability to guarantee dependable and consistent performance. Our strict quality control measures ensure that we maintain our high standards.

Connect Us Now

Maintenance Guide for Diamond Dresser tools

| Maintenance Steps | Description |

|---|---|

| Cleaning | Clean with water or a cleaning agent before and after use to avoid impurities and debris that may cause damage. Regular cleaning is recommended when working in dusty environments. |

| Storage | Store in a dry, ventilated, and dust-free environment when not in use, using a dedicated storage box or rack to avoid squeezing and collision. |

| Replacement | Timely replacement when the Diamond Dresser is worn or failed to ensure processing accuracy and efficiency. Pay attention to the operation method to avoid collision or damage to other components. |

| Lubrication | Lubricate to reduce friction and wear during use, using specialized lubricants or grinding oils suitable for Diamond Dressers. |

| Regular Inspection | Regular inspection is necessary during use to ensure its effectiveness and wear condition. Any abnormalities found should be addressed promptly through maintenance or replacement to avoid affecting processing performance. |

problems and solutions

Poor grinding effect and high surface roughness.

- 1

Check whether the grinding parameters, such as feed rate and speed, are reasonable;

- 2

Check whether the Diamond dresser is worn, and replace it in time if it is worn;

- 3

Check whether the grinding fluid is clean and replace it if necessary.

The diamond dresser is prone to wear.

- 1

Choose suitable grinding parameters, such as feed rate and speed;

- 2

Pay attention to lubrication and cooling during use, and choose suitable grinding or cooling fluid;

- 3

Regularly check the wear of the Diamond dresser, and replace it in time if necessary.

A lot of heat is generated during processing.

- 1

Choose suitable grinding or cooling fluid to ensure that the Diamond dresser does not overheat during processing;

- 2

Regularly check the work of the lubrication and cooling system, and repair it in time if abnormalities are found.

A lot of dust is generated during processing.

- 1

Choose suitable grinding or cooling fluid to reduce dust generation;

- 2

Regularly clean the processing site and equipment to prevent excessive dust accumulation.

A lot of dust is generated during processing.

- 1

Choose suitable grinding parameters, such as feed rate and speed; pay attention to the cleaning and lubrication of the Diamond dresser, and keep its surface smooth;

- 2

Regularly check the wear of the tool and fixture, and replace them in time if abnormalities are found.

frequently asked questions for Diamond Dresser tools and catalogs

FAQ

Most frequent questions and answers

Please click the contact form, submit your contact information, then describe your detailed requirements and upload the files with PDF, Dxf, or step. Our professional engineers will contact you within 12 hours

Please do not worry, click the contact form, and please describe your needs in detail, our technical engineer will contact you after receiving it. Free

We are very sorry that all reamers are custom-made according to the customer’s requirements. So we don’t have any in stock.

The delivery time depends on the complexity of the tool, the size of the tool size, and the purchasing quantity. Big data shows that for the straight handle reamer with less than 4 teeth, we usually take about 7-15 days to finish them. 15-25 days for HSK handle BT handle reamers and 20-35 days for flange handle reamers.

Dear customers, We will 100% inspect all dimensions of every diamond dresser tool before shipment and generate detailed inspection reports. We will deliver them to you together with the tools.

We placed great emphasis on the safety, timeliness, and efficiency of transportation. So we only cooperate with the best international logistics companies, such as DHL, UPS, and FedEx. We can accept EXW, FOB, DAP, DDP, and other service terms.

We are a direct tooling manufacturer, and T/T transfer is available. For the sample with a small amount, we can also accept credit cards, papal, western union, etc.