CBN (PCBN) Turning Inserts

CBN (PCBN) Overview

CBN (PCBN) is a material with a hardness second only to synthetic diamonds. It is produced through the transformation of a catalyst under high temperature and pressure conditions. CBN (PCBN) is a type of inorganic super-hard material and boasts high hardness, chemical inertness, and thermal stability at high temperatures.

CBN (PCBN) Turning Inserts Application

PCBN is widely used for cutting, particularly in the machining of high-hardness and difficult-to-machine materials. It is ideal for CNC turning operations to produce precision-hardened parts with a highly polished surface. CBN/PCBN turning inserts are primarily used for high-speed machining of hard metals such as hardened steel, powdered metal, superalloys, and cast iron. These inserts are specially designed for aerospace and automotive applications.

Our Capacity

Our CBN/PCBN turning inserts are engineered for longer tool life and uniform surface finish, as well as exceptional dimensional control. As a result, component costs can be reduced, leading to higher productivity and cost savings in the overall manufacturing process.

Toughness Behaviour

Indexable CBN (PCBN) Turning Inserts

We offer a variety of indexable CBN/PCBN turning inserts. You can provide the tool model based on the ISO designation key, and we will manufacture the appropriate inserts to match the tool’s application and material performance. These indexable inserts are commonly used for turning, boring, and as part of a replaceable tooling system.

Tipped CBN (PCBN) Turning Inserts

Full Edge CBN (PCBN) Turning Inserts

Full Face/Soild CBN (PCBN) Turning Inserts

| Work Material | Grade | Cutting Speed(m/min) | Feed(mm/rev) | Depth of Cut(mm) | Recommandation |

|---|---|---|---|---|---|

| Al alloy(4-9%Si) | >55HRC | 80~120 | 0.3~1.5 | 0.08~0.2 | CBN300/500 CBN900 |

| <56HRC | 80~150 | 0.5~2.0 | 0.1~0.25 | CBN300/500 | |

| Gray Cast Iron | 180-230 HB | 500~1500 | 0.1~2.0 | 0.15~0.4 | CBN750,CBN900 |

| Ductile Cast Iron | 200~700 | 0.3~2.0 | 0.1~0.4 | CBN450 | |

| Rolls(Chilled Cast Iron) | >55 HRC | 80~120 | 0.3~2.0 | 0.1~0.3 | CBN900 |

| Powdered Metal | <35 HRC | 100~300 | 0.3~2.0 | 0.1~0.3 | CBN500,CBN900 |

| >35HRC | 50~200 | 0.3~2.0 | 0.1~0.3 | CBN500,CBN900 |

Connect with the Sundi Tools Sales Team

The Material Behavior

CBN 300/500

Low content CBN, Excellent thermo-chemical wear resistance

- High speed cut for hardened steel and bearing steel in continuous to the light interrupted mode

- High-speed cut for ductile cast iron in continuous mode

CBN 450/600

Low content CBN, Excellent thermo-chemical with optimum toughness

- General grade for hardened steels in continuous to the interrupted mode

- Hardened alloy steel and tool steel in continuous to the light interrupted mode

- Ductile cast iron and gray cast iron to the interrupted cutting mode

CBN 750

Minimum content CBN, Optimum chemical and abrasion wear resistance

- Soft powdered metal in continuous to the light-interrupted cutting mode

- Ductile cast iron in continuous to the light-interrupted cutting mode

CBN 900/950

High content CBN, Excellent fracture toughness and abrasion wear resistance

- Outstanding performance in turning and milling of cast iron

- Hard powder metal in continuous to the severe interruption

- Hardened steel and tool steel in interrupted cutting mode.

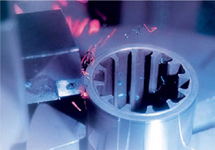

User Case Of CBN (PCBN) Turning Inserts

Work material: Hardened steel,57-62HRC

,V(m/min)=100,f(m/rev)=0.1,d(mm)=0.15mm

One set of inserts can be machined over 500 pcs workpiece, better dimensions and surface roughness control.

10 times working life increased over other material inserts.

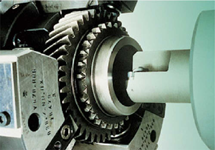

Face turning of half shaft HRC55-60 20CrNiMoH

V(m/min)=170 f=0.22 D(mm)=0.1

Increased 15% tooling life increased over competitors, at the same working parameter.

Greatly reduced the user’s cost