solid tungsten carbide end mill

solid carbide end mill CNC router bits for steel, aluminum, stainless steel(SUS), graphite, copper etc..

Engineered Carbide End Mill Solution

With decades of experience in designing and manufacturing carbide end mill cutter bits, Sundi provides expert support to machining manufacturers. Our engineering expertise and intelligence enable us to create custom-engineered solutions for any quantity, big or small, to improve productivity.

Unser Auftrag

Our goal is to achieve total customer satisfaction through the endless pursuit of excellence in solutions, quality, and service.

Unsere Kapazität

We offer a wide range of carbide end mill cutter bits for roughing and finishing operations, available in standard or special designs. They can be manufactured as solid carbide or with coolant capabilities.

We Are One Of Best Carbide End Mill Maker

Sundi designs and manufactures tungsten carbide end mills for clients around the world in various industries. Our end mills are suitable for rough or precision processing of materials such as copper, copper alloys, cast iron, carbon steel, mild steel, stainless steel, titanium alloys, nickel alloys, aluminum, aluminum alloys, plastics, heat-treating steel, and more, to achieve the required finish and accuracy of parts.

Whether for milling, turning, or drilling processes, our proven full product life cycle process enables us to optimize tools. We specialize in developing cutting tool solutions to improve the quality of products and increase production efficiency for our clients. They can be manufactured as solid carbide or coolant.

- Hohe Genauigkeit und Effizienz

- Hochgeschwindigkeits-Schneidvorschub

- Hervorragende Rauhigkeit

- Weniger Prozessschritte Geringe Zykluszeit

- Maximale Lebensdauer der Werkzeuge

- Nachschleifen zur Kostensenkung

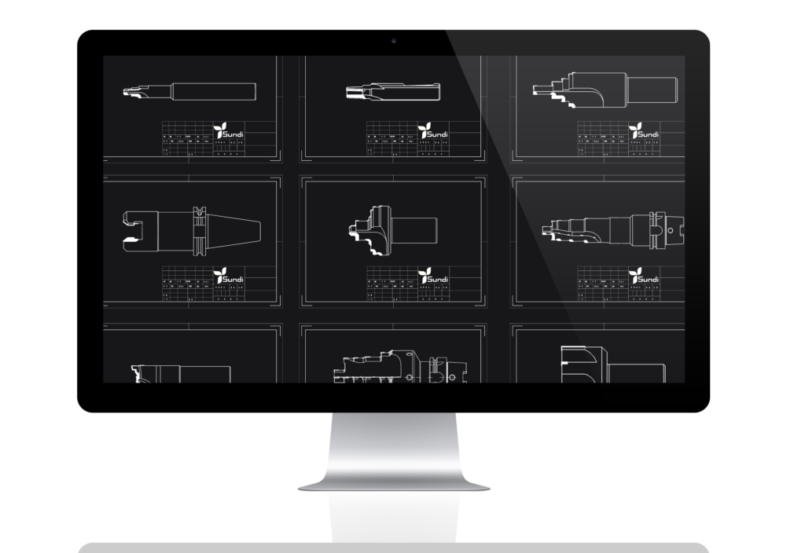

find the carbide end mill set with different form

Verbinden Sie uns jetzt

find the carbide end mill bits with different application

Material Application of Carbide End Mill Cutter

Verbinden Sie sich mit dem Sundi Tools Verkaufsteam

Application of Carbide end mill Cutter

Carbide end mill cutters are versatile tools used in CNC machines, engraving machines, and standard milling machines to process heat-treated hard and moderately complex materials. Their hardness usually ranges from HRA93-97, almost as hard as diamonds, which makes them durable and brittle for specific applications. They are also not annealed, making them suitable for a wide range of jobs.

Luft- und Raumfahrt

Automotive

Medical

Machinery

Was uns anders macht

-

7×24 Stunden

7x24Hrs online für technische Unterstützung

-

Gestaltung

Neugestaltung und 3D-Formenbau

-

Kosten senken

Die gleiche Qualität im Vergleich zu den Top-Marken, aber die Hälfte oder ein Viertel der Kosten.

-

3 Tage

Schnelle Reaktion innerhalb von 3 Tagen von der Zeichnungsfreigabe bis zur Lieferung

-

Expressversand

Weltweiter Versand (UPS, DHL, FedEx, TNT)

-

1 Jahr Garantie

Qualitätssicherung und sorgenfreier Kundendienst bis zu 12 Monate lang

Qualifizierter Rohstoff auf hohem Niveau

We source our tungsten carbide rods from Japan or Germany to ensure top quality. Our end mill set, with its consistent material performance, surpasses comparable products on the market.

Ungleiche Nuten Design gegen die Vibration

End mill sets with flutes that have sharp cutting edges and an unequal design can increase cutting efficiency by up to 300% due to their anti-vibration design.

OEM-Dienst

Mit unserem OEM-Service helfen wir Ihnen, Ihr eigenes Logo oder Ihre eigene Verpackung zu gestalten.

Advanced Production Techniques

The use of chamfered radius helps to prevent tool collisions while Walter machines ensure consistent dimensions in our production process.

World-class Coating Service-BALZERS

We are dedicated to offering our customers world-class coating services and constantly introduce new technologies to extend the service life of our products.

Maßgeschneiderter Service

Our competent technical team offers unique machining solutions through our custom-made service.

Common the end mill Coating Performance

| BESCHICHTUNG | Farbe | Härte | MAX.Arbeitstemperatur | Schichtdicke |

|---|---|---|---|---|

| TIN | Bronze | 2400HV | 600°C | 1-7μm |

| TIALN | Violet Black | 3500HV | 800°C | 1-4μm |

| TISIN | Bronze | 3900HV | 1000°C | 2-4μm |

| DLC | Black | 2800HV | 400°C | 1-3μm |

| NACO BLUE | Blue | 4500HV | 1200°C | 2-3μm |

| DIAMOND | Black | 10000HV | 800°C | 0.5-1.5μm |

| TICN | Black Grey | 3200HV | 400°C | 1-4μm |

User Case of Carbide End Mill Cutters

Diamond coating milling cutter for graphite

5.7 x

1.3 x

-

D780

Used Tool

-

Graphit

Arbeitsmaterial

-

Fertigbearbeitung

Prozess

-

110m/min

Cutting speed

-

800mm/min

Futtermittel

-

Emulsion

Kühlmittel

Ball nose milling cutter for aluminum

10.3 x

5.4 x

-

AL550

Used Tool

-

Aluminium

Arbeitsmaterial

-

Profile machining

Prozess

-

150m/min(8000 min)

Cutting speed

-

1500mm/min

Futtermittel

-

Emulsion

Clooant

Ball nose milling cutter for hard steel

2.0 x

1.2 x

-

S650

Used Tool

-

Steel HRC60

Arbeitsmaterial

-

Profile machining

Prozess

-

150m/min(8000 min)

Cutting speed

-

1500mm/min

Futtermittel

-

Emulsion

Clooant

Verbinden Sie uns jetzt

the steps show How we made the carbide end mill

- Schritt 1: Analyse und Entwurf

-

Schritt 1: Analyse und Entwurf

By thoroughly communicating with our customers and gaining a deeper understanding of their requirements, including accuracy, roughness, and tool lifespan, we can fabricate high-quality carbide milling tools tailored to specific applications.

- Schritt 2: Auswahl des geeigneten Materials

-

Schritt 2: Auswahl des geeigneten Materials

We carefully select tungsten carbide rods with varying specifications and performance characteristics based on their intended uses. Our shank diameter tolerance is 0/-0.005mm, reducing vibrations during high-speed cutting.

- Schritt 3:Produziert von Walter

-

Schritt 3:Produziert von Walter

We use Walter machines for both cutting tool production and re-grinding, and they perform excellently in terms of increasing efficiency. The Walter machine body has a high deadweight and rigidity, that effectively reduces vibration impact and ensures high grinding accuracy. With a stock of 24 grinding wheels, our machines can handle complex geometry structures and large-scale milling cutter production.

- Schritt 4: Messen

-

Schritt 4: Messen

After the completion of carbide end mill production, we conduct a comprehensive test on each tool using Zoller equipment to measure every diameter, angle, and arc. All tools must pass the program's checks before they are sent to our QC department.

- Schritt 5: Beschichtung

-

Schritt 5: Beschichtung

Coating is a chemical and thermal barrier that reduces diffusion and chemical reactions between the tool and the workpiece, thus reducing matrix wear. End mills that undergo coating have many advantages, including high surface hardness, good wear resistance, stable chemical properties, heat and oxidation resistance, low friction coefficient, and low thermal conductivity characteristics. Coated end mills have a cutting life increased by 3-5 times more than an uncoated tool, increased cutting speed by 20%-70%, improved processing accuracy by 0.5-1 level, and reduced total cost by 20%-50%.

- Schritt 6: Verpackung und Lieferung

-

Schritt 6: Verpackung und Lieferung

Before packaging and shipping, our expert quality control team tests the tools for dimensions and surface finish to ensure they meet our high standards.

Störungsbeseitigung

Manchmal treten bei der Verwendung der festen Einsätze Probleme auf. Die folgenden Situationen sind typisch

Schneidemesser borken

Werkzeug gebrochen

- 1

Vorschubgeschwindigkeit zu hoch

die Vorschubgeschwindigkeit reduzieren

- 2

Die Schnittrichtung ist nicht richtig

die Richtung geändert

- 3

Klinge zu scharf

Anfasen und Abrunden der Schnittkante

- 4

Werkzeuge nicht gut befestigt

Überprüfung und Befestigung der Spannzange

- 5

Vibration

die Wendegeschwindigkeit zu verringern

- 1

zu viel Schnittleistung

die Schnittparameter zu reduzieren

- 2

Widerstand zu stark reduzieren

den Vorschub reduzieren, die Drehgeschwindigkeit erhöhen

- 3

Zu lange Werkzeuge

Einstellen der geeigneten Werkzeuge

Zu schnelle Abnutzung

- 1

Vorschubgeschwindigkeit zu niedrig

die Vorschubgeschwindigkeit erhöhen

- 2

Die Schnittrichtung ist falsch

die Schnittrichtung geändert

- 3

Die Härte des Materials ist zu hoch

die geeigneten und richtigen Werkzeuge auswählen

Oberflächenrauhigkeit schlecht

- 1

Vibration

Einstellen der Schnittparameter

- 2

Chip entfernen schlecht

Einstellung der Emulsion, Erhöhung der Schnittgeschwindigkeit

- 3

Vorschubgeschwindigkeit zu hoch, aber niedrige Drehgeschwindigkeit

die richtigen Schnittparameter einstellen

Recycle and Regeneration of Carbide End Mills

Recycle with Re-grinding and Coating

We don’t just offer high-efficiency carbide end mills, we also provide recycling services through re-grinding and coating to reduce tooling costs. Normally, the grinding process only uses 20-30% of new tools but can increase the tool’s working life by over 70%. The proper coating also extends the tool’s life.

Regeneration and Coating

Are you concerned that old tools may no longer work with updated production processes due to changes in dimensions?

We offer regeneration services that update the diameter, shapes, and applications of tools to ensure compatibility with new production processes. The proper coating also extends the tool’s life.