When it comes to precision cutting in various applications, Cubic Boron Nitride (CBN) cutters are among the most effective tools available. However, selecting the right CBN cutter for your specific application is crucial to achieving optimal results. In this comprehensive guide, we will walk you through the key factors to consider when choosing a CBN cutter to ensure that it perfectly suits your needs.

Understanding Cubic Boron Nitride (CBN) Cutters

Before diving into the factors to consider, let’s understand what CBN cutters are and why they are highly sought-after in the machining industry. Cubic Boron Nitride is a synthetic material that exhibits exceptional hardness, making it second only to diamond in terms of hardness. This incredible hardness allows CBN to excel in cutting and machining various materials, including hardened steels, superalloys, and other tough-to-machine substances.

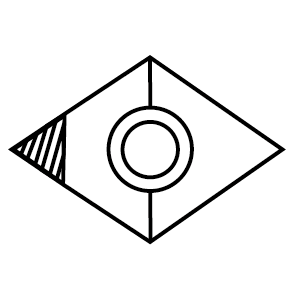

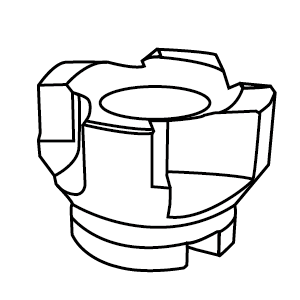

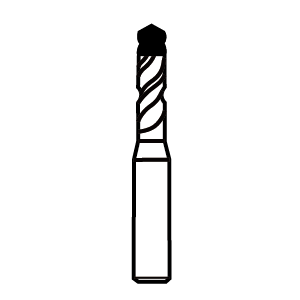

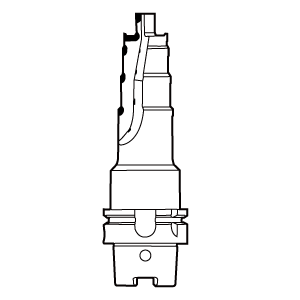

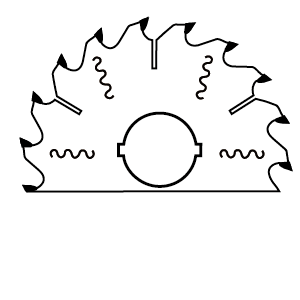

CBN cutters are available in various forms, including inserts, solid end mills, and brazed tools, among others. Each form has its own set of advantages and is suitable for specific applications. By choosing the right form of CBN cutter, you can significantly enhance the productivity and quality of your machining processes.

Factors to Consider When Selecting a CBN Cutter

- **Material Compatibility:**

The first and foremost factor to consider is the material you intend to cut. Different CBN cutters are designed to work optimally with specific materials. For example, if you are working with hardened steel, you’ll need a CBN cutter with a specific grade and coating that can handle the high cutting forces and temperatures associated with such materials.

- **Cutting Speed and Feed Rate:**

The cutting speed and feed rate are critical parameters that directly impact the performance of a CBN cutter. To achieve the best results, you must choose a cutter that can handle the cutting speed and feed rate required for your application. It is essential to match these parameters with the capabilities of the CBN cutter to ensure efficient material removal and surface finish.

- **Cutter Geometry and Type:**

CBN cutters come in various geometries and types, such as single-point, multi-point, round inserts, and square inserts, among others. The choice of cutter geometry and type depends on factors like the complexity of your machining operation, the desired surface finish, and the material hardness. Understanding the specific requirements of your application will help you make the right choice.

- **Coolant and Lubrication:**

CBN cutting generates high temperatures during the machining process. Therefore, proper coolant and lubrication play a crucial role in maintaining tool life and workpiece integrity. Choosing the right coolant and lubrication method that suits your application will ensure better chip evacuation and heat dissipation.

- **Machine Compatibility:**

It is vital to ensure that the selected CBN cutter is compatible with your machining equipment. Check the cutter dimensions, mounting options, and tool holder specifications to ensure a seamless fit into your machinery.

- **Surface Finish Requirements:**

If your application demands a superior surface finish, selecting the appropriate CBN cutter with the right cutting-edge preparation and tool coating is essential. The right cutter will help you achieve the desired surface roughness and reduce the need for secondary finishing processes.

Applications and Benefits of CBN Cutters

CBN cutters find applications in various industries, such as aerospace, automotive, energy, and medical, where high precision and durability are paramount. Some of the key benefits of using CBN cutters include:

- **High Hardness:** CBN cutters can handle materials with extreme hardness, ensuring consistent performance and prolonged tool life.

- **Improved Productivity:** By choosing the right CBN cutter, you can increase machining speeds and feed rates, leading to higher productivity and reduced cycle times.

- **Superior Surface Finish:** CBN cutters can achieve excellent surface finishes, reducing the need for additional finishing processes and saving time and costs.

- **Cost-Effectiveness:** While CBN cutters may have a higher initial cost than conventional tools, their extended tool life and improved productivity result in long-term cost savings.

- **Versatility:** CBN cutters can be used on a wide range of materials, making them a versatile choice for various applications.

Conclusion

Choosing the right CBN cutter is crucial for achieving exceptional results in your machining applications. By considering factors like material compatibility, cutting speed, cutter geometry, coolant, and machine compatibility, you can select the perfect CBN cutter for your specific needs. Remember to prioritize the requirements of your application and aim for a cutter that enhances productivity, surface finish, and overall efficiency.

Now that you have a solid understanding of CBN cutters and their selection process, you are well-equipped to make an informed decision. Investing in the right CBN cutter will undoubtedly pay off in terms of improved performance and cost savings in the long run.

If you want to learn more information about the CBN cutter pls visit here