Master Steel Machining with Carbide Mill Bits: 7 Types Unveiled!

Unlock the secrets of steel machining with our comprehensive guide on carbide mill bits. Discover 7 types of carbide mill bits and their applications for mastering steel machining.

When it comes to machining steel, precision, and effectiveness are the cornerstones of success. The right tools can make all the difference, and one tool that stands out in the world of steel machining is the carbide mill bit. In this guide, we delve deep into the realm of carbide mill bits, exploring 7 end mill cutter types that can elevate your steel machining endeavors to new heights. Whether you’re a seasoned professional or a novice in the field, this article will equip you with the knowledge you need to master steel machining using carbide mill bits.

What are the types of carbide end mill bits?

Carbide mill bits have redefined steel machining, offering durability, precision, and versatility. Let’s dive into 7 types of carbide end mill bits for steel that can be your allies in conquering steel.

- Square End Mill Bit: Precision Personified

The square-end mill bit is a versatile workhorse in steel machining. Its sharp corners and straight edges make it ideal for creating 90-degree angles and clean, flat-bottomed cuts. From slotting to profiling, this type of carbide mill bit is your go-to choice for precision work.

- Ball Nose End Mill Bit: Sculpting with Finesse

For 3D profiling and sculpting steel surfaces, the ball nose end mill bit takes the spotlight. Its rounded tip enables smooth blending and contouring, making it perfect for adding intricate details to your steel projects while maintaining a consistent radius.

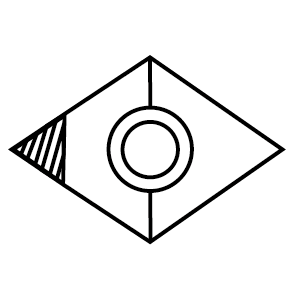

- Corner Radius End Mill Bit: The Edge of Perfection

When you need to prevent chipping and enhance tool life, the corner radius end mill bit steps in. With its rounded corners, it smoothly transitions between vertical and horizontal surfaces, delivering both precision and durability.

- Roughing End Mill Bit: Conquering Tough Terrain

Dealing with tough steel that needs rapid material removal? The roughing end mill bit is your ally. Its coarse teeth quickly remove excess material, preparing the workpiece for finer finishing passes.

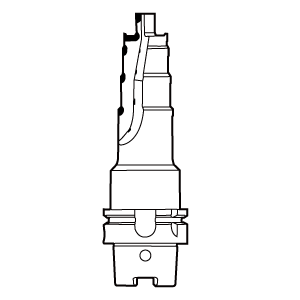

- Tapered End Mill Bit: Elegance in Tapering

Creating tapered holes and surfaces in steel demands finesse, and the tapered end mill bit delivers just that. It’s gradually decreasing diameter allows you to achieve smooth transitions and intricate designs.

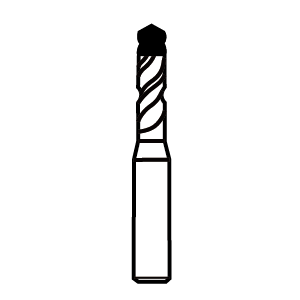

- Drill Mill Bit: Drilling and More

When drilling and milling are both on the agenda, the drill mill bit is your answer. With its combined functionality, it efficiently creates holes while also performing milling tasks, saving time and effort.

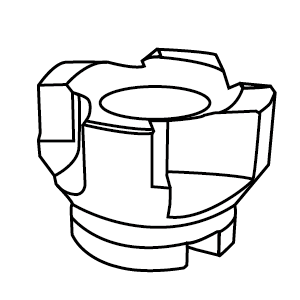

- High-Feed End Mill Bit: Speed and Efficiency

When you need high material removal rates with reduced cutting forces, the high-feed end mill bit shines. It facilitates rapid cutting and is excellent for steel applications where productivity is paramount.

How to choose the right carbide milling bits for your steel machining project?

Selecting the ideal carbide mill bit for your steel project requires careful consideration of several factors. Here’s a guide to help you make the right choice.

- Material Hardness Matters

Different steel alloys have varying levels of hardness. Opt for carbide milling bits designed for the specific hardness of the steel you’re working with to ensure longevity and efficiency.

- Cutting Speed and Feed Rate

Balancing cutting speed and feed rate is crucial. Adjust these parameters based on the tool’s recommendations and the specific requirements of your project to achieve optimal results.

- Depth of Cut: Finding the Sweet Spot

Determining the appropriate depth of cut prevents tool overload and promotes stable cutting. Consult the manufacturer’s guidelines and experiment to find the perfect balance.

- Surface Finish: From Rough to Polished

Consider the desired surface finish for your project. Some carbide mill bits excel at roughing, while others are designed for smooth finishes. Match the tool to your finishing needs.

FAQs - Frequently Asked Questions

Q: Can I use carbide mill bits on other materials besides steel?

A: Yes, carbide mill bits are versatile and can also be used on materials like aluminum, plastics, and composites.

Q: Do carbide mill bits require special maintenance?

A: Regular inspection, proper lubrication, and keeping the tool’s edges sharp are essential for maintaining carbide mill bits.

Q: Can I use ceramic inserts for hard turning?

A: While ceramic inserts are primarily designed for machining hardened steel, they can be used for hard-turning operations as well.

Q: What’s the advantage of using corner radius end mill bits?

A: Corner radius end mill bits reduce the risk of chipping and extend tool life, making them ideal for intricate or delicate operations.

Q: Are carbide mill bits suitable for high-speed machining?

A: Yes, the heat resistance and durability of carbide make it suitable for high-speed steel machining.

Q: Can I use square-end mill bits for drilling?

A: While not their primary purpose, square-end mill bits can create holes, but drill mill bits are more efficient for drilling operations.

Q: Where can I find reliable information about carbide mill bit specifications?

A: Manufacturer catalogs, machining forums, and reputable online resources provide valuable insights into carbide mill bit specifications.

Mastering steel machining requires the right tools, and carbide mill bits are at the forefront of precision and versatility. With 7 types of end mill bits unveiled, you now possess a toolkit to tackle a range of steel projects. Remember, choosing the right tool involves considering factors like material hardness, cutting speed, and finish requirements. Armed with this knowledge, you’re ready to embark on your steel machining journey with confidence.