Introduction Of Carbide Drills Bits Set & Our Capacity

Our Mission

We aim to offer total customer satisfaction with the endless pursuit of Excellence in Solutions, Quality, and Service.

Engineered carbide drill bits Solution

We have decades years of experience in designing and manufacturing carbide drills to support machining manufacturers. Sundi offers the best practices, engineering, and intelligence to allow us to focus on creating custom-engineered solutions, whether it’s small or mass quantity, we can generate the best solution to improve productivity.

Our Capacity

We manufacture a wide range of standard and customized drill bit set with different geometries, coating, and diameters. They are manufactured using the latest state-of-the-art automated CNC tool grinders, which allow us to manufacture high-level carbide drills at a competitive cost.

Sundi Tools has decades yeas of experience in designing and manufacturing standard or customized carbide drills with coating or non-coating to support leading manufacturers with initial on-site consultation, design assist and machining optimization.Whatever milling, turning or drilling processing, the tools can be optimized by our proven full product life cycle process. We are not only specialized in developing cutting tools solutions to improve their products quality, but also help clients increase the production efficiency.

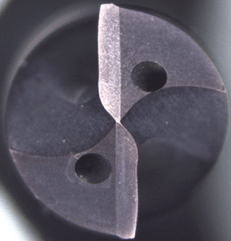

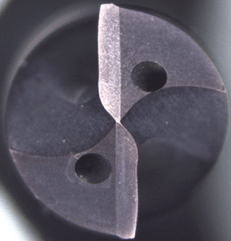

Construction Introduction of Solid Carbide Drill Bits Sets

- 1

The straight main cutting blade

- 2

Smooth and big radius

- 3

Sharp drill point

- 4

Curve chip room make shorter chips

- 5

Big chip room

Super grade carbide material

We choose the suitable carbide material for steel and aluminum, with high wear resistance and great stability.

| Coating | Color | Hardness of Coating | Max temperature | Friction Coefficient | Surface Roughness | wear resistance | compatibility |

|---|---|---|---|---|---|---|---|

| DLC | Black/iridescence | HV5000 | 450° | 0.05 | ★ | ★ | ☆ |

Specification of Solid Carbide Drill Bits Sets

Workpiece Material

| Coolant | Work piece material | Diameter | Length of flute |

|---|---|---|---|

| for steel / cost iron | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D | ||

| for steel / cost iron | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D |

Workpiece Material

| Coolant | Work piece material | Diameter | Length of flute |

|---|---|---|---|

| for aluminum/ cooper/ nonferrous metal | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D | ||

| for aluminum/ cooper/ nonferrous metal | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D |

User Case of Soild Carbide Drill Bits Sets

| User Application | |

|---|---|

| Workpice Material | 42CrMo |

| Application | Drill |

| Cutting Speed | 80m/min |

| Feed | 980mm/min |

| Dill deep | 14mm |

| Coolnat | emulsion |

| Device | HAAS |

| User Application | |

|---|---|

| Workpice Material | SUS304 |

| Application | Drill |

| Cutting Speed | 70m/min |

| Feed | 943mm/min |

| Dill deep | 24mm |

| Coolnat | emulsion |

| Device | BT50 |