What Is Carbide Reamer

The Carbide Reamer is a high-precision tool designed for perfecting holes. It’s crafted from solid carbide or equipped with welded carbide blades, making it extremely durable and wear-resistant. This tool is all about precision, ensuring holes have the right diameter and a smooth finish, which are crucial for top-notch manufacturing. Its design guarantees it stays accurate for a long time, offering consistent quality across your projects.

Thanks to advanced 5-axis Walter grinders or Vollmer wire cutting technology, each reamer is shaped with precision within 0.002mm. This meticulous process ensures the reamer’s accuracy and form, contributing to the high-quality output of your manufacturing process.

Main application of carbide Reamer

Carbide Reamers are pivotal in automotive, aerospace, electronics, and medical industries for precision hole-making. They ensure high accuracy and durability, critical for components demanding exact fits and superior finishes.

carbide Reamer manufacturer

At Sundi Tools, we craft our Carbide Reamers from premium carbide for unmatched precision and durability. Our meticulous shaping and polishing, followed by a protective coating, ensure each tool’s superior performance.

Our commitment to quality is unwavering. Every step, from material selection to the final inspection, upholds the highest standards, ensuring our tools exceed client expectations and reinforce our reputation for excellence.

- durable alloy materials maintain cutting edge sharpness

- stable performance in high-speed cutting for efficient material removal

- suitable for various materials reducing production costs

- tailored to specific machining needs

- longer lifespan means fewer replacements

- achieve high-quality , accurate workpieces.

Automotive Industry

Aerospace

Sector

Medical Device Production

Valves and Seals Industry

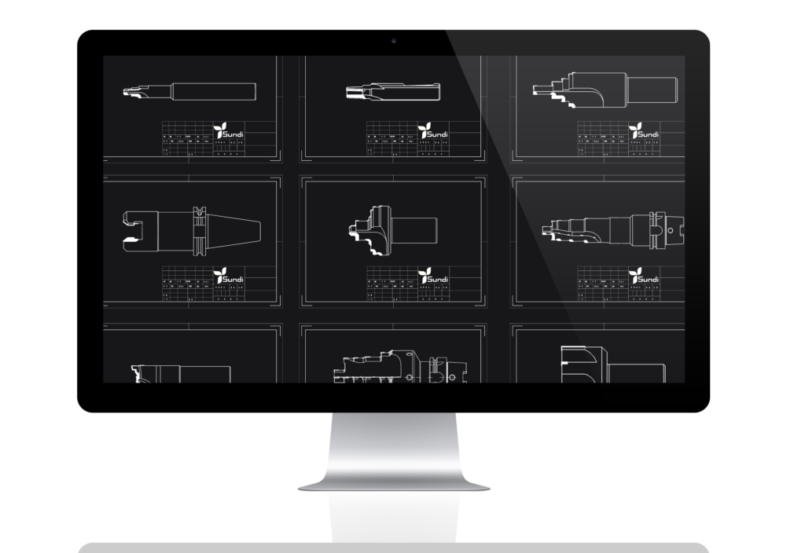

Find The Carbide reamer With Different Form

Coolant Mechanism by Application

Coolant provides effective cooling and lubrication in high-speed,high-precision reaming applications. They help reduce cutting temperatures,improve cutting performance, extend tool life, and maintain a clean and stable cutting zone.

For Blind Holes(Center Coolant)

For Through Holes

Common Forms of Coolant Holes

Double straight coolant hole

Double spiral coolant hole

Single coolant hole

Single straight both side coolant hole

Connect with the Sundi Tools Sales Team

Application of Carbide reamer full form

Who we are

What made us different

-

7×24 Hrs

7x24Hrs online for technical supports

-

3D mold

Re-design and 3D mold building

-

1/2 cost

The same quality compared with the top-brand, but half or quarter cost.

-

7 Days

Fast reaction as fast as 7 days from drawing approval to delivery

-

3 days shipping

Worldwide shipment (UPS,DHL,FedEx,TNT)

-

1 year Warranty

Quality assurance and after-sales without worries for as long as 12months

How we made the tools

- Step 1 Aalysis and Design

-

Step 1 Aalysis and Design

With consumer plenarily communication, Deepens know consumer requirement, According to consumer requirements, including accuracy, roughness, working life. We will fabricate qualified Carbide reamers for different applications.

- Step 2 Rough Machining of Carbide Reamer

-

Step 2 Rough Machining of Carbide Reamer

Rough machining shapes the Carbide Reamer, involving CNC turning, milling, and cylindrical grinding to pre-machine the alloy rod, setting a precise margin. This stage lays the groundwork for detailed flute creation and subsequent fine machining.

- Step 3 Vacuum Brazing of Carbide Reamer(optional)

-

Step 3 Vacuum Brazing of Carbide Reamer(optional)

Vacuum brazing securely attaches Carbide blades to the steel shank, using silver solder in brazing grooves. The assembly is then heated in a vacuum furnace at 800 degrees for 20 minutes, ensuring the solder melts and bonds tightly. This method guarantees the Carbide tips remain fixed during high-speed operations or under strong impacts, ideal for reamers requiring alloy tips.

- Step4 5-Axis Fluting and Grinding

-

Step4 5-Axis Fluting and Grinding

We use advanced 5-axis machines to precisely shape and smooth our Carbide Reamers. This step allows us to create complex shapes with high accuracy, making sure each tool performs well and lasts longer. The machines work on the reamer from different angles, ensuring every detail is perfect. This process shows our commitment to making high-quality tools using the latest technology, ready for tough jobs.

- Step5 Fine Grinding

-

Step5 Fine Grinding

For jobs needing smooth finishes, like in aluminum, we fine grind the Carbide Reamer's edge. This makes the tool's finish much better and reduces vibration when cutting holes, improving the work quality. We aim for a super tight accuracy, up to 0.002mm, ensuring our reamers work perfectly and last longer.

- Step 6 Measurement and Quality Control

-

Step 6 Measurement and Quality Control

After completing the wire cutting or grinding, we thoroughly test each tool on a Zoller machine. This checks every diameter, angle, and arc to ensure they meet our strict standards. Each tool's dimensions are verified by specialized software before moving to quality control. Tools with HSK and BT shanks undergo a dynamic balance test to confirm the concentricity of the Carbide reamer is within 0.002mm during rotation, guaranteeing precision and reliability in use.

- Step 7 Surface Treatment

-

Step 7 Surface Treatment

The final step involves applying a coating to the Carbide reamer, tailored to specific customer needs, especially for cast iron and hardened steel applications. In partnership with Oerlikon, we use the most advanced and precise coating technologies available. This ensures our tools not only meet but exceed performance expectations in durability and efficiency, catering to the specialized requirements of our clients.

frequently asked questions for carbide reamer and catalogs

FAQ

Most frequent questions and answers

Please click the contact form, submit your contact information, then describe your detailed requirements and upload the files with PDF, Dxf, or step. Our professional engineers will contact you within 12 hours

Please do not worry, click the contact form, and please describe your needs in detail, our technical engineer will contact you after receiving it. Free

We are very sorry that all reamers are custom-made according to the customer’s requirements. So we don’t have any in stock.

The delivery time depends on the complexity of the tool, the size of the tool size, and the purchasing quantity. Big data shows that for the straight handle reamer with less than 4 teeth, we usually take about 7-15 days to finish them. 15-25 days for HSK handle BT handle reamers and 20-35 days for flange handle reamers.

Dear customers, We will 100% inspect all dimensions of every reamer before shipment, and generate detailed inspection reports. We will deliver to you together with the tools.

We placed great emphasis on the safety, timeliness, and efficiency of transportation. So we only cooperate with the best international logistics companies, such as DHL, UPS, and FedEx. We can accept EXW, FOB, DAP, DDP, and other service terms.

We are a direct tooling manufacturer, and T/T transfer is available. For the sample with a small amount, we can also accept credit cards, papal, western union, etc.