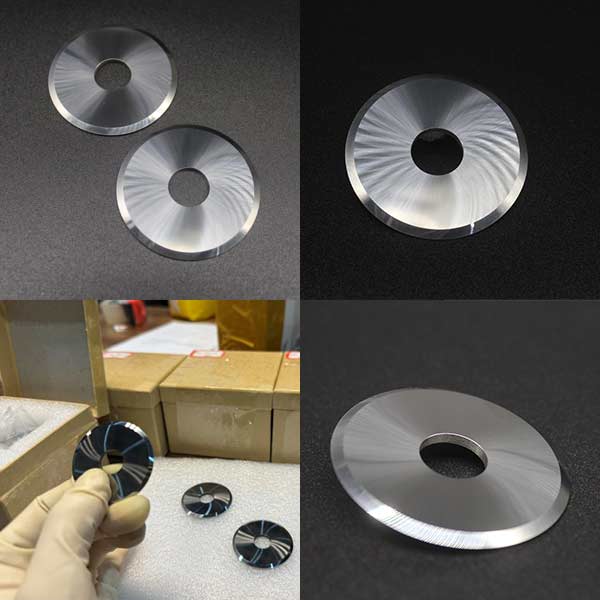

circular knife blade,Precision circular Slitting Knives

Sundi Tools offers premium circular knives and cutting blades suitable for a variety of applications, from industrial to commercial to heavy-duty projects. Our product range includes blades and circular knives designed to fulfill diverse requirements. In addition to manufacturing a broad array of circular blades for OEM parts, we excel in producing custom blades tailored to meet the specific cutting and processing demands of our customers. Continue reading to discover more about our circular knives and blades, or Contact our sales team,you will get a quick reply.

What is circular knife blade?

A circular knife blade is a type of circular slitter blade, primarily used to cut sheets into strips or smaller sheets of the desired width. Constructed from tungsten carbide, these blades are known for their durability and sharpness. Designed to be mounted on rotary machines, circular knife blades are highly versatile and can be used across various applications, such as paper, cardboard, tubing, packaging, printing, tape, plastic films, rubber, synthetic fibers, non-woven fabrics, aluminum and copper foils, leather, synthetic materials, medical dressings, sanitary materials, and food.

Circular slitter blades, which include circular knife blades, are available in various sizes and shapes to suit different materials and cutting needs. The circular knife blade, in particular, is a circular disc with a finely honed edge that slices cleanly through materials. These blades are characterized by their sharp cutting edges, low cutting angles, and lack of teeth, making them ideal for precision slitting operations.

Commonly used in industries requiring precise cuts and minimal material wastage, circular knife blades are essential tools for ensuring efficient and accurate production processes.

Advantages Of using circular knife blade

Precision Cutting

These blades deliver precise and accurate cuts, ensuring high-quality results with each use.

Cost Efficiency:

By minimizing material waste and enhancing operational efficiency, circular slitter blades help to reduce production costs significantly.

Adaptability:

They are capable of cutting a broad array of thin and flexible materials such as paper, film, and foil, making them highly versatile tools in various industrial applications.

- Quality Assurance

- OEM/ODM Service

- Cost Saving

- Fast Delivery

Blades for a Wide Range of Industries

Sundi Tools is proud to manufacture a variety of circular knife styles for a diverse range of industries. Our customers come from sectors including paper, cardboard, tubing, packaging, printing, tape, plastic films, rubber products, synthetic fibers, non-woven fabrics, aluminum foil, copper foil, leather, synthetic materials, medical dressings, sanitary materials, and the food industry. Whether your company operates within these industries or requires a unique blade for a different sector, we look forward to collaborating with you to create your custom blade.

Customized Circular knife Blades

At Sundi Tools, our expert team specializes in designing custom blades tailored to meet the specific cutting and processing needs of our customers. Whether for industrial applications or smaller-scale projects, we are confident in our ability to provide the precise blades your team requires to complete your tasks. We offer free quotes for our customized blade creation services. Contact us today for a consultation and to receive your free quote.

- Quality Assurance

- OEM/ODM Service

- Cost Saving

- Fast Delivery

Blades for a Wide Range of Industries

Sundi Tools is proud to manufacture a variety of circular knife styles for a diverse range of industries. Our customers come from sectors including paper, cardboard, tubing, packaging, printing, tape, plastic films, rubber products, synthetic fibers, non-woven fabrics, aluminum foil, copper foil, leather, synthetic materials, medical dressings, sanitary materials, and the food industry. Whether your company operates within these industries or requires a unique blade for a different sector, we look forward to collaborating with you to create your custom blade.

Customized Circular knife Blades

At Sundi Tools, our expert team specializes in designing custom blades tailored to meet the specific cutting and processing needs of our customers. Whether for industrial applications or smaller-scale projects, we are confident in our ability to provide the precise blades your team requires to complete your tasks. We offer free quotes for our customized blade creation services. Contact us today for a consultation and to receive your free quote.

Why Choosing us

Customization

We offer customized Circular knife Blades to match specific customer needs, including size.

Technical expertise

Our team has extensive technical expertise in cutting tools and machining processes, ensuring that our customers receive expert guidance and support.

Competitive Pricing

We offer competitive pricing for our high-quality Circular knife Blades, helping to reduce tooling costs for our customers.

Exceptional customer service

We prioritize exceptional customer service and are dedicated to providing our customers with timely, accurate, and friendly support throughout the ordering process and beyond.

Manufacturing Process of Circular knife Blades

Cutting:

Circular slitter blades are crafted by either stamping or using CNC laser cutting techniques on metal sheets. The method chosen depends on the desired shapes and specific applications of the final blades.

Heating:

Once cut to shape, the blades undergo a sequence of heat treatments. These processes harden and temper the metal, enhancing its strength and durability for prolonged use.

Sharpening:

Post heat treatment, the blades are initially sharpened to remove any surface flaws. This is followed by a grinding process that finely hones the edges, making them exceptionally sharp.

Coating:

To further enhance their performance, the tips of the circular slitter blades can be coated with materials like chromium or tungsten. These coatings significantly improve the blades’ resistance to wear and corrosion, extending their operational life.

Circular knife Blades are produced through a meticulous manufacturing process. Initially, high-quality materials such as high-carbon steel or carbide are selected based on the blade’s intended application and durability requirements. These materials are then precision-cut into circular shapes. The cutting edges are meticulously ground to achieve sharpness and accuracy, ensuring that each blade can deliver precise and clean cuts. Finally, the blades undergo heat treatment to enhance their hardness and wear resistance, preparing them for a variety of cutting tasks in industrial settings. This comprehensive process guarantees that circular slitter blades meet high standards of quality and performance.