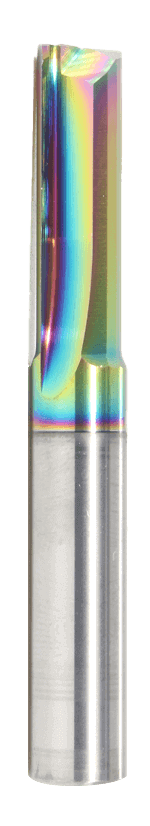

Double-flute spiral straight cut router bits

Overview

Double flute spiral straight router bits are a type of cutting tool used with a router machine and are available in a range of sizes and diameters. They have two flutes, or cutting edges, that spiral around the bit in a helical pattern, they have a straight cutting edge for precise cuts and minimal chipping. They are also designed with a straight shank for easy and secure clamping in the router collet. The spiral straight-cut router bits help to remove chips and debris from the cutting surface, which reduces heat and friction and prolongs the life of the bit.

Mainly Application

Double-flute spiral straight cut router bits are commonly used in a variety of applications, including:

- Woodworking: Double-flute spiral straight-cut router bits are often used for creating grooves, dados, and other straight cuts in wood, such as for joinery and cabinetry.

- Cabinetry: Double-flute spiral straight-cut router bits are used to create precise cuts for cabinet parts, including grooves for shelves and panels.

- Sign-making: Double-flute spiral straight-cut router bits are commonly used in the sign-making industry to create straight cuts and clean edges.

Wood Router Bits

Soild Carbide Milling Cutter:

Connect Us Now

advantages of spiral straight cut router bits

Smooth cutting

These bits remove material more swiftly and smoothly because of their double-flute spiral design. Also, the spiral flutes aid in lowering heat buildup, which could otherwise result in burning and harm to the wood.

Reduced tear-out

The clean, smooth cuts made by double-flute spiral straight-cut router bits aid to lessen tear-out and splintering. This is crucial when working with pricey or delicate wood.

Versatility

Double-flute spiral straight-cut router bits can be used for a variety of woodworking projects, including edge trimming, mortising, and dado cutting.

Increased chip clearance

The double-flute design of these bits aids in the rapid removal of chips and debris, reducing the chance of blockage and overheating.

Improved Control

The spiraled flutes of the bit can provide improved control, especially when working with handheld routers, allowing for greater accuracy and precision.

Longer Bit Life

Double-flute spiral straight cut router bits are easy to use, even for beginners. The bullnose shape makes them ideal for creating round-over edges or decorative details.

The Most Typical Of Double-flute spiral straight cut router bits For Different Applications

| Item Code | Outside Diameter | Flute Length | Overall Length | Shank Diameter |

|---|---|---|---|---|

| WS-2-D312 | 3.175 | 12 | 38 | 3.175 |

| WS-2-0422 | 4 | 22 | 45 | 4 |

| WS-2-0625 | 6 | 25 | 50 | 6 |

| WS-2-0852 | 8 | 52 | 80 | 8 |

| WS-2-1030 | 10 | 30 | 60 | 10 |

| WS-2-1080 | 10 | 80 | 120 | 10 |

| WS-2-10100 | 10 | 100 | 150 | 10 |

we are the best CNC Router Bits set manufacturers

At SUNDI, our goal is to provide you with the most cost effective and the best solutions. Our expertise, solutions, and technical support make us the ideal partner for tackling tasks, overcoming challenges, and completing projects successfully.

Professional

we have multi top class production lines which help us to offer better performance tools and extend the range of our products.

Quality

Every year, we spend a lot of money upgrading and maintaining our equipment.

in stock

We have an ample supply of goods in stock.

Team

We follow standard procedures and have an excellent team of designers.

OEM

We have many years of leading OEM and ODM manufacturing experience in this field.

Delivery

Receiving goods as fast as 3 days around the world.

Connect with the Sundi Tools Sales Team

Working principle of Double-flute spiral straight cut router bits

- To remove material from a workpiece, double-flute spiral straight cut router bits use a combination of rotation and cutting edges.

- Two flutes wrap around the bit, guiding it through the material and preventing jams and scorching. They can be used to make a variety of cuts, such as plunge cuts, through cuts, and edge cuts.

- The dual-flute design offers stability and control, resulting in precise and accurate cuts.

- Depending on the application and material being routed, these bits can be composed of carbide, high-speed steel, or diamond. The bit’s shank is designed to fit into a router collet or chuck and can be straight or tapered depending on the type of router utilized.

Choosing the Right Double-flute spiral straight cut router bits

Choosing the right spiral straight router bits depends on several factors, . Taking the time to select the appropriate router bit can result in a cleaner, smoother cut, and a better end result.

1. Material

Consider the type of material you will be routed, as different materials require different types of router bits. For example, hardwoods may require a bit with a carbide cutting edge, while softer materials like MDF may be better suited to a high-speed steel bit.

2. Cutting depth

- The cutting depth of the bit should also be regarded. A bit with a longer cutting length would be used if you need to make a deep cut.

3. Flute length

- The length of the spiral flutes can also impact bit performance. Longer flutes may be more efficient at chip removal, but shorter flutes may be more stable and controlling.

4. Speed

- Check that the router bit is appropriate for the speed at which your router runs. Running a bit at the incorrect speed might result in overheating and a bit of damage.

5. Coating

- Look for router bits with specialized coatings such as carbide or diamond, which can improve durability and performance.

6. Shank size

- Inspect the shank size of the router bit to ensure that it is compatible with your router. Most router bits have a shank diameter of 1/4-inch or 1/2-inch, although some routers may require a different size.

7. Brand and quality

- Consider the reputation of the brand and the quality of the router bit. A high-quality router bit will last longer and perform better, making it a worthwhile investment for your workshop.

Tips for Using Double-flute spiral straight cut router bits

- 1

Safety first

Always wear eye and ear protection when using any router bit, including bullnose bits.

- 2

Adjust router speed

Adjust the speed of the router to match the hardness and thickness of the material being cut. A slower speed may be necessary for harder materials to prevent the bit from overheating.

- 3

Make a test cut

Make a test cut on a scrap piece of material before cutting the actual workpiece. This will help you adjust the depth and speed of the cut for the best results.

- 4

Secure the workpiece

Use clamps or a router table to secure the workpiece and prevent it from moving during the cut.

- 5

Begin with the end grain

Start the cut on the end grain of the workpiece, and then move the router to the long grain. This will help prevent tear-out on the end grain.

- 6

Make multiple passes

To create a smooth and even edge, make multiple passes with the router bit, gradually increasing the depth of cut each time.

- 7

Keep the bit clean

Clean the bit periodically during use to remove any buildup of debris or material that may interfere with its cutting ability.