Introduction of the Special Tools

Overview

When processing products made of composite materials, traditional tools can be ineffective and easily damaged, making it difficult to meet processing demands. In such situations, we can design personalized products according to customer needs. These products include special PCD/CBN inserts, special shape cutting inserts, PCD/CBN router bits/countersinks, PCD/CBN grooving tools/bits, shanked tools, rolling bits, and custom-made mills and drills. These tools are mainly used for specific applications, such as special inserts for machining aluminum alloy wheel hubs, groovers for machining piston grooves, and router bits for machining stones.

Depending on the application, we will select the appropriate PCD/CBN material and processing technology to assure the tools’ abrasion resistance and stability. We can assist customers to achieve increased processing efficiency and higher-quality finished products by providing customized and specialized tools.

Features and Advantages

- Longer working life.

- Customizable to clients’ processing needs.

- Reliable stability.

- Excellent surface finish.

- Reduced clamping and adjusting time.

Main Products Of Special Tools

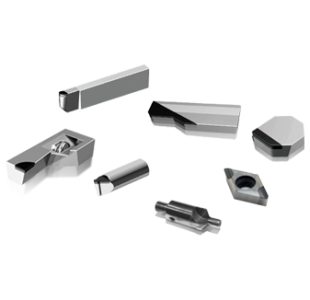

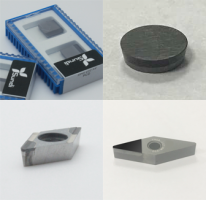

Special PCD/CBN Inserts

Sundi provides a wide range of special PCD/CBN inserts that can be customized to meet specific customer requirements. To meet the unique needs of our clients, we can modify the cutting-edge length or shape of standard inserts. For example, with full face, solid inserts, and full edge inserts, we can extend the cutting edge’s length, increase or reduce the radius based on the customer’s special request, or add a chip break in the blade.

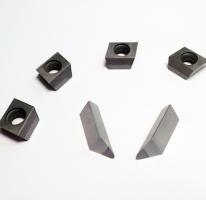

Special Shape cutting Inserts

The special shape cutting inserts are fundamentally distinct from standard inserts due to their unique shapes and cutting-edge angles. These inserts can be redesigned to suit specific customer requirements and cost considerations. We also offer assembly holders to our clients.

PCD CBN Router Bit/Countersink

In special milling and hole machining processes, PCD/CBN router bits play a critical role in improving productivity. These tools are commonly used for locating and machining small or special holes.

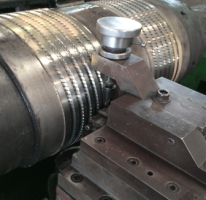

PCD/CBN Grooving Tools / Bit, Shanked Tools

PCD/CBN grooving tools/bits and shanked tools are primarily utilized for grooving and internal shape/groove machining. They are commonly used in the machining of piston sealing grooves, which is a widely used application. The width of the grooving cutting edge and the depth of the radius can be adjusted according to customer requirements. PCD/CBN grooving tools offer excellent impact and abrasion resistance, as well as high precision, which can significantly lower production costs for users.

Rolling Bit

We usually use the PC material with high Grade to tip in the tool body. They’re normally applied in engraving the carbide rolling parts or hard material. Compared with carbide material, the PCD material has a super hardness, So the PCD rolling bit improves the working life and reduces the cost during heavy duty.

Custom-Made Mills & Drills

Custom mills and drills from Sundi can have one or more chamfers added to or removed from the cutting edge depending on regular versions. These tools can be customized to match particular customer requirements and are perfect for machining precision holes.