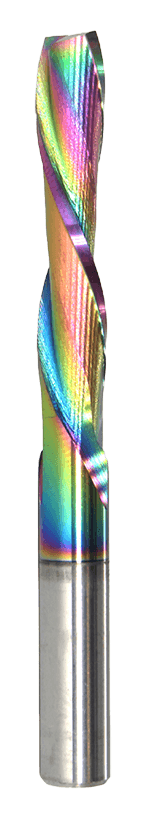

Single and Double-flute spiral downcut router bits

Overview

Single and Double-flute spiral downcut router bits are cutting tools used in woodworking with a portable or CNC router. The single-flute variant, featuring a single helix groove, is ideal for quickly and efficiently removing material during tasks like end milling, grooving, and pocketing. Using the single flutes spiral down-cut router bits on softer materials such as wood, MDF, and plastic produces smoother and more accurate cuts.

On the other hand, Double-flute spiral downcut router bits feature two helical grooves that balance the cut, reducing chatter and vibration. This design is more appropriate for harder materials such as steel, brass, and aluminum, and provides smoother and more accurate cuts, making it an excellent choice for applications where surface smoothness is important.

Mainly Application

Spiral downcut router bits are used for downward cutting in woodworking or materials that tend to chip or splinter. They have a smooth cutting action, remove debris efficiently, and create clean edges on materials such as plywood or laminates. They are also suitable for carving and engraving designs and for use in CNC milling.

Wood Router Bits

Soild Carbide Milling Cutter:

Connect Us Now

advantages of Double-flute spiral downcut router bits

Clean cuts

The downward spiral of the bit pulls chips and debris down and away from the cutting surface, resulting in a cleaner cut with less tear-out and fraying.

Reduced splintering

As the bit cuts into the material, the downward spiral also helps to compress the fibers of the material, reducing the likelihood of splintering.

Improved accuracy

The downward spiral of the bit helps to keep the cutting surface flat and level, which can improve accuracy and reduce the need for additional sanding or finishing.

Dust and debris removal

The spiraling flutes on the router bit help to remove chips and debris from the cutting surface, reducing heat and friction, and prolonging the life of the bit.

Improved cutting speed

Spiral downcut router bits enable higher cutting speeds due to their downward flutes, which prevent material from slipping or moving during cutting.

Reduced heat buildup

The spiral flutes also help to dissipate heat more effectively, reducing the risk of burning or melting the material being cut.

The Most Typical Of Spiral downcut router bits For Different Applications

| Item Code | Outside Diameter | Flute Length | Overall Length | Shank Diameter |

|---|---|---|---|---|

| WD-1-0312 | 3 | 12 | 38 | 3 |

| WD-1-D317 | 3.175 | 17 | 38 | 3.175 |

| WD-1-0422 | 4 | 22 | 50 | 4 |

| WD-1-0525 | 5 | 25 | 50 | 5 |

| WD-1-0632 | 6 | 32 | 60 | 6 |

| WD-1-D642 | 6.35 | 42 | 76 | 6.35 |

| WD-1-D732 | 7.9 | 32 | 60 | 7.9 |

| WD-1-0842 | 8 | 42 | 70 | 8 |

| WD-1-D962 | 9.525 | 62 | 101 | 9.525 |

| WD-1-10100 | 10 | 100 | 150 | 10 |

| WD-1-1280 | 12 | 80 | 120 | 12 |

| WD-1-D1255 | 12.7 | 55 | 101 | 12.7 |

| WD-2-0328 | 3 | 28 | 50 | 3 |

| WD-2-D328 | 3.175 | 28 | 50 | 3.175 |

| WD-2-0425 | 4 | 25 | 50 | 4 |

| WD-2-D625 | 6.35 | 25 | 60 | 6.35 |

| WD-2-0862 | 8 | 52 | 80 | 8 |

| WD-2-10100 | 10 | 100 | 150 | 10 |

| WD-2-D1262 | 12.7 | 62 | 115 | 12.7 |

we are the best CNC Router Bits set manufacturers

At SUNDI, our goal is to provide you with the most cost effective and the best solutions. Our expertise, solutions, and technical support make us the ideal partner for tackling tasks, overcoming challenges, and completing projects successfully.

Professional

we have multi top class production lines which help us to offer better performance tools and extend the range of our products.

Quality

Every year, we spend a lot of money upgrading and maintaining our equipment.

in stock

We have an ample supply of goods in stock.

Team

We follow standard procedures and have an excellent team of designers.

OEM

We have many years of leading OEM and ODM manufacturing experience in this field.

Delivery

Receiving goods as fast as 3 days around the world.

Connect with the Sundi Tools Sales Team

Working principle of spiral downcut router bits

Part 1:

The spiral flutes on a spiral downcut router bit pull chips and debris downward as the bit cuts into the material.

Part 2:

The helical shape of the flutes clears chips and debris from the cutting path effectively, preventing them from getting trapped between the bit and the material.

Part 3:

The downward motion of the flutes helps to prevent tear-out and splintering on the top surface of the material.

- Other types of router bits, such as straight-cut bits, push chips and debris up and out of the cutting path, causing them to get trapped between the bit and the material. This can lead to tear-out and splintering on the top surface of the material.The downward motion of the flutes on a spiral down-cut router bit helps to avoid this issue, resulting in a cleaner and smoother cut on both sides of the material being cut.

Choosing the Right Spiral Downcut Router Bits

Choosing the right spiral down-cut router bits depends on several factors, including the type of material being cut, the desired finish, and the specific application. Taking the time to select the appropriate router bit can result in a cleaner, smoother cut, and a better end result.

1. The kinds of materials getting cut

Spiral down-cut router bits are widely used for cutting materials that fracture and tear, such as plywood, melamine, and MDF.

2. The desired outcome

- A router bit with closer spacing between the flutes may be preferable for a smoother finish. However, this can cause additional heat to be generated during the cutting process.

- A router bit with wider flute spacing can assist clear chips and dirt more effectively, but it may not offer as clean a cut.

3. The specific application

- if the material being cut is thin, a router bit with a shorter cutting length may be needed to prevent excessive flexing or bending. If the material being cut has a highly decorative surface, a router bit with a more decorative profile may be desired.

Tips for Using Spiral Downcut Router Bits

- 1

Use the appropriate feed speed

Too fast of a feed speed can cause the bit to overheat and burn the material, while too slow of a feed speed can cause the bit to bog down and create an uneven cut.

- 2

Use the appropriate cutting depth

The cutting depth should be adjusted based on the thickness of the material being cut. Cutting too deep can cause the bit to flex or break while cutting too shallow can create an uneven cut.

- 3

Use the appropriate router speed

The router speed should be regulated according to the diameter of the bit being used. Bits having larger diameters should be used at slower rates, while bits having smaller diameters can be used at faster speeds.

- 4

Keep the bit clean

Chips and debris can build up on the bit during use, which can affect its performance. It's important to periodically clean the bit with a brush or compressed air to remove any buildup.

- 5

Use the appropriate safety gear

Router bits can be dangerous if not used properly. Always wear eye and ear protection when using a router, and consider using a dust mask or respirator to protect against dust and debris.