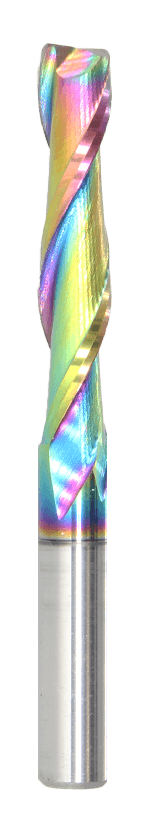

Single and Double-flute spiral Upcut router bits

Overview

Single and Double-flute spiral Upcut router bits are a type of cutting tool used in woodworking and other materials which need upward cutting performance. The difference between the two is the number of flutes, or cutting edges, on the bit. Unlike the spiral down-cut router bits, the spiral upcut router bits are designed to pull the material up and away from the cutting surface, rather than pushing it down. This design allows for cleaner cuts, as well as improved chip evacuation, as the upward cutting action helps to remove debris from the cutting area more efficiently.

Mainly Application

Spiral upcut router bits are popular for routing grooves, slots, and precision cuts in materials like wood and plastic. They leave a clean edge and produce less tear-out than other types of bits, making them a preferred choice for woodworking. However, they may not be the best choice for materials that are prone to splintering or chipping, and they generate heat while in use, requiring proper cooling and lubrication to avoid tool or material damage.

Wood Router Bits

Soild Carbide Milling Cutter:

Connect Us Now

advantages of Double-flute spiral Upcut router bits

Improved chip evacuation

The spiral upcut design pulls chips and debris up and out of the cut, reducing the likelihood of clogging or burning. This is particularly useful when cutting softer materials, such as wood or plastic.

Improved cutting speed

Spiral upcut router bits can be used at higher speeds than other types of router bits. This is because the upward motion of the flutes helps to keep the material in place, reducing the likelihood of slipping or moving during the cutting process.

Cleaner top surface

The flutes pull chips and debris up and away from the material being cut, upcut router bits typically leave a cleaner top surface with less tear-out and splintering.

Better suited for softer materials

Upcut router bits are generally better suited for cutting softer materials, such as plastics and composites, as well as softer woods like pine and cedar.

Can be used for plunge cutting

Upcut router bits can be used for plunge cutting, allowing for the creation of grooves and slots in the material being cut.

Reduced heat buildup

The spiral flutes also help to dissipate heat more effectively, reducing the risk of burning or melting the material being cut.

The Most Typical Of Spiral Upcut router bits For Different Applications

| Item Code | Outside Diameter | Flute Length | Overall Length | Shank Diameter |

|---|---|---|---|---|

| WU-1-0312 | 3 | 12 | 38 | 3 |

| WU-1-D317 | 3.175 | 17 | 38 | 3.175 |

| WU-1-0422 | 4 | 22 | 50 | 4 |

| WU-1-0525 | 5 | 25 | 50 | 5 |

| WU-1-0632 | 6 | 32 | 60 | 6 |

| WU-1-D642 | 6.35 | 42 | 76 | 6.35 |

| WU-1-D732 | 7.9 | 32 | 60 | 7.9 |

| WU-1-0842 | 8 | 42 | 70 | 8 |

| WU-1-D962 | 9.525 | 62 | 101 | 9.525 |

| WU-1-10100 | 10 | 100 | 150 | 10 |

| WU-1-1280 | 12 | 80 | 120 | 12 |

| WU-1-D1255 | 12.7 | 55 | 101 | 12.7 |

| WU-2-0328 | 3 | 28 | 50 | 3 |

| WU-2-D328 | 3.175 | 28 | 50 | 3.175 |

| WU-2-0425 | 4 | 25 | 50 | 4 |

| WU-2-D625 | 6.35 | 25 | 60 | 6.35 |

| WU-2-0862 | 8 | 52 | 80 | 8 |

| WU-2-10100 | 10 | 100 | 150 | 10 |

| WU-2-D1262 | 12.7 | 62 | 115 | 12.7 |

we are the best CNC Router Bits set manufacturers

At SUNDI, our goal is to provide you with the most cost effective and the best solutions. Our expertise, solutions, and technical support make us the ideal partner for tackling tasks, overcoming challenges, and completing projects successfully.

Professional

we have multi top class production lines which help us to offer better performance tools and extend the range of our products.

Quality

Every year, we spend a lot of money upgrading and maintaining our equipment.

in stock

We have an ample supply of goods in stock.

Team

We follow standard procedures and have an excellent team of designers.

OEM

We have many years of leading OEM and ODM manufacturing experience in this field.

Delivery

Receiving goods as fast as 3 days around the world.

Connect with the Sundi Tools Sales Team

Working principle of spiral Upcut router bits

- Spiral upcut router bits work by using the spiraling flutes on the bit to pull chips and debris up and away from the material being cut.

- The cutting edge of the bit rotates clockwise as it moves through the material, while the spiraling flutes on the bit move in a counterclockwise direction.

- This creates a cutting action that pulls chips and debris up and out of the cutting area, rather than pushing them down into the material being cut.

Chips and debris are effectively removed from the cutting area as they are lifted up and away from the material, reducing the risk of clogging and enhancing overall cutting performance. The upward action of the flutes also aids in heat dissipation, lowering the risk of burning or melting the material being cut.

Choosing the Right Spiral UpCut Router Bits

Choosing the right spiral upcut router bits depends on several factors. Taking the time to select the appropriate router bit can result in a cleaner, smoother cut, and a better end result.

1. Material

Different materials require different types of router bits. Consider the material you will be cutting and choose a bit that is specifically designed for that material. For example, a bit designed for cutting plastics may not work well for cutting hardwoods.

2. Bit diameter

- The size of the cut will depend on the router bit’s diameter. Choose a bit whose diameter corresponds to the size of the cut you intend to make.

3. Cutting depth

- Consider the depth of the cut you need to make and choose a bit with a cutting length that matches that depth. Using a bit with a cutting length that is too short may result in incomplete cuts, while using a bit that is too long may cause excessive strain on the router motor.

4. Flute length and number

- The length and number of flutes on the router bit can affect the cutting performance. Longer flutes can help to dissipate heat more effectively, while more flutes can provide a smoother cut. Consider the specific needs of your project and choose a bit with the appropriate flute length and number.

5. Shank size

- The shank size of the router bit must match the collet size of the router. Check the specifications of your router to ensure that the bit you choose will fit properly.

6. Quality

- Choose a high-quality router bit from a reputable manufacturer. A quality bit will last longer and provide better cutting performance than a cheaper, lower-quality bit.

Tips for Using Spiral UpCut Router Bits

- 1

Maintain a consistent feed rate

Spiral up-cut router bits are designed to pull chips and debris up and out of the cut. To ensure that the bit can do its job effectively, maintain a consistent feed rate throughout the cut. This will prevent the bit from becoming bogged down and will help to prevent burn marks on the workpiece.

- 2

Use the appropriate speed

Like all router bits, Spiral up-cut router bits perform best when used at the appropriate speed. Check the manufacturer's recommendations for the recommended speed for the specific bit you are using, and adjust the speed of the router accordingly.

- 3

Monitor the temperature

Because spiral up-cut router bits are designed to pull chips and debris up and out of the cut, they can generate a significant amount of heat. Be sure to monitor the temperature of the bit and the workpiece during use, and take breaks as needed to allow the bit and workpiece to cool down.

- 4

Use the proper technique

When using a spiral up-cut router bits, it's important to use the proper technique. Keep the router base flat on the workpiece, and move the router in a smooth and controlled manner. This will help to prevent tear-out and ensure a clean, precise cut.

- 5

Keep the bit sharp

A dull router bit will not cut as cleanly or efficiently as a sharp one. Be sure to sharpen your spiral up-cut router bit regularly, or replace it when necessary, to ensure optimal cutting performance.