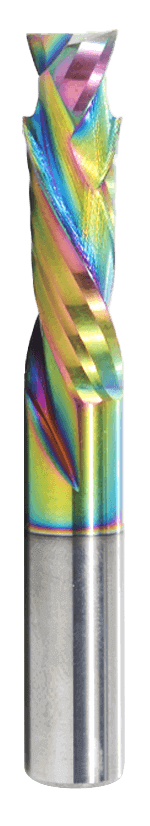

Single and Double-flute spiral Compression cut router bits

Overview

Double-flute spiral compression router bits are a type of cutting tool commonly used in woodworking and other materials that require clean, precise cuts with minimal tear-out. These router bits are designed with two flutes that spiral in opposite directions, which helps to compress and shear the material being cut, rather than simply slicing through it. The compression router bits offer a cleaner and more precise cut by drastically reducing the incidence of chip-out and tear-out. These bits’ Double-flute design also works very well in dense materials, but it also lessens vibrations during cutting. This makes for a smoother, more accurate cut, and is perfect for jobs requiring a high degree of precision.

Mainly Application

Double-flute spiral compression router bits are particularly useful for materials that are prone to chipping or splintering, such as hardwoods, laminates, and MDF.

Spiral compression router bits are commonly used for a variety of routing applications, including creating grooves, dados, and slots, as well as for decorative edge treatments and other precision cuts. They are also useful for cutting mortises. These router bits are popular for use in CNC router machines, as their precision cutting action can help to reduce production time and waste. They are also commonly used by woodworkers who require a high level of precision and a professional-looking finish.

Wood Router Bits

Soild Carbide Milling Cutter:

Connect Us Now

advantages of Double-flute spiral compression cut router bits

Clean cuts

Spiral compression-cut router bits produce clean cuts on both the top and bottom of the workpiece, which is especially important when working with laminates or veneers.

Reduced chip-out

The cutting edges of a spiral compression-cut router bit alternate between up-cut and down-cut, they can help to reduce chip-out and tear-out, even on delicate or brittle materials.

Improved finish quality

Because spiral compression-cut router bits compress the material as they cut, they can help to produce a smoother, more polished finish.

Increased feed rate

Spiral compression-cut router bits can be used at higher feed rates than other types of bits, which can save time and improve efficiency.

Versatility

Spiral compression-cut router bits can be used on a wide range of materials, including wood, plastics, and composites.

Reduced heat buildup

Because spiral compression-cut router bits remove chips and debris so efficiently, they generate less heat than other types of router bits.

The Most Typical Of Spiral Compression cut router bits For Different Applications

| Item Code | Outside Diameter | Flute Length | Overall Length | Shank Diameter |

|---|---|---|---|---|

| WC-2-0321 | 3 | 21 | 50 | 3 |

| WC-2-D317 | 3.175 | 17 | 45 | 3.175 |

| WC-2-D425 | 4.76 | 25 | 63.5 | 4.76 |

| WC-2-0625(64) | 6 | 25 | 64 | 6 |

| WC-2-D631(76) | 6.35 | 31 | 76.2 | 6.35 |

| WC-2-D722 | 7.9 | 22 | 63.5 | 7.9 |

| WC-2-0825 (64) | 8 | 25 | 64 | 8 |

| WC-2-D925 | 9.525 | 25 | 76.2 | 12.7 |

| WC-2-1035 | 10 | 35 | 75 | 10 |

| WC-2-1232 (75) | 12 | 32 | 75 | 12 |

| WC-2-D1231 | 12.7 | 31.75 | 76.2 | 12.7 |

| WC-2-D1254 | 12.7 | 54 | 127 | 12.7 |

| WC-2-D1231(B) | 12.7 | 31 | 76.2 | 12.7 |

| WC-2-D1235 | 12.7 | 35 | 89 | 12.7 |

| WC-2-D1250 | 12.7 | 38 | 101.6 | 12.7 |

we are the best CNC Router Bits set manufacturers

At SUNDI, our goal is to provide you with the most cost effective and the best solutions. Our expertise, solutions, and technical support make us the ideal partner for tackling tasks, overcoming challenges, and completing projects successfully.

Professional

we have multi top class production lines which help us to offer better performance tools and extend the range of our products.

Quality

Every year, we spend a lot of money upgrading and maintaining our equipment.

in stock

We have an ample supply of goods in stock.

Team

We follow standard procedures and have an excellent team of designers.

OEM

We have many years of leading OEM and ODM manufacturing experience in this field.

Delivery

Receiving goods as fast as 3 days around the world.

Connect with the Sundi Tools Sales Team

Working principle of spiral Compression cut router bits

- By compressing the material as they cut, spiral compression-cut router bitsThis is made possible by a special layout that includes two spiraling flutes that wrap around the bit’s body. The material is pulled into the center of the bit by the flutes as it rotates, compressing it as it is cut.

- As the bit spins, the up-cut flutes force material upward and into the down-cut flutes.

- These down-cut flutes then compress the material, resulting in a clean, smooth cut with minimal tear-out or splintering.

- Traditional router bits frequently experience chip-out, which is an issue that spiral compression-cut router bits assist to avoid. When the material being cut separates from the bit’s edge, the result is a rough or jagged cut, which is known as chip-out. Spiral compression-cut router bits reduce chip-out and make cleaner, smoother cuts by compressing the material as they cut.

Choosing the Right Spiral Compression Cut Router Bits

Choosing the right spiral compression-cut router bits depends on several factors. Taking the time to select the appropriate router bit can result in a cleaner, smoother cut, and a better end result.

1. Material

Consider the type of material you will be cutting, such as wood, plastic, or metal. Different materials require different types of router bits with specific cutting edges and coatings.

2. Size

- Choose the appropriate size of router bit for your project. This includes the diameter and length of the bit, as well as the shank size to ensure compatibility with your router.

3. Cutting depth

- Consider the depth of cut required for your project. Some spiral compression-cut router bits are designed for shallow cuts, while others can handle deeper cuts.

4. A Number of flutes

- The number of flutes on a router bit can affect the cutting speed and quality of the cut. Spiral compression-cut router bits typically have two flutes, but some may have more or less depending on the application.

5. Coating

- Look for router bits with specialized coatings such as carbide or diamond, which can improve durability and performance.

6. Brand and quality

- Consider the reputation of the brand and the quality of the router bit. A high-quality router bit will last longer and perform better, making it a worthwhile investment for your workshop.

Tips for Using Spiral Compression Cut Router Bits

- 1

Use the right feed rate

It's critical to use the right feed rate in order to get the best results. A router bit that is fed at too high or low a rate can break or wear out too quickly or produce a poor-quality cut. The material being cut, the bit's diameter, and the depth of the cut will all affect the feed rate.

- 2

Use the appropriate cutting speed

The cutting speed of the router bit should be appropriate for the material being cut. A slower cutting speed is usually required for harder materials such as metals, while softer materials like wood can be cut at a faster speed.

- 3

Use proper safety equipment

When using any type of router bits, it is important to wear appropriate safety equipment such as safety glasses, hearing protection, and a dust mask. This will protect you from any debris or dust generated during the cutting process.

- 4

Keep the bit clean and sharp

Keeping the router bit clean and sharp is essential for achieving the best results. Clean the bit regularly with a cleaning solution and ensure that the cutting edges are sharp and free of any nicks or chips.

- 5

Use the appropriate router

Ensure that the router you are using is appropriate for the size and shank diameter of the spiral compression-cut router bit. Using the wrong router can cause damage to the bit or the machine.